| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : Shinden

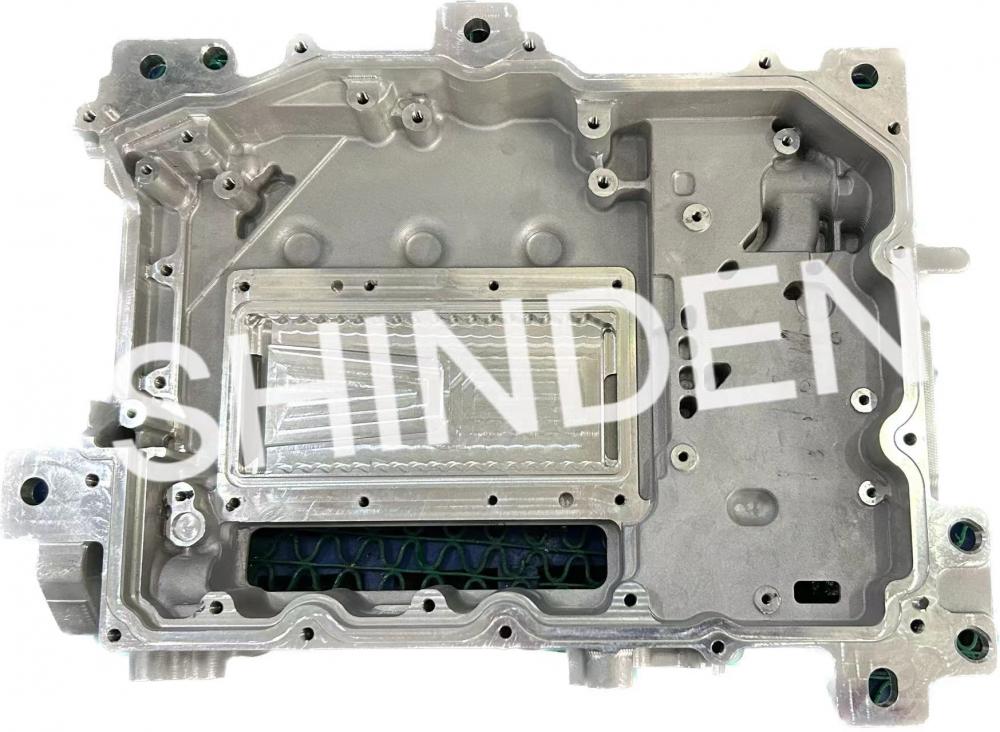

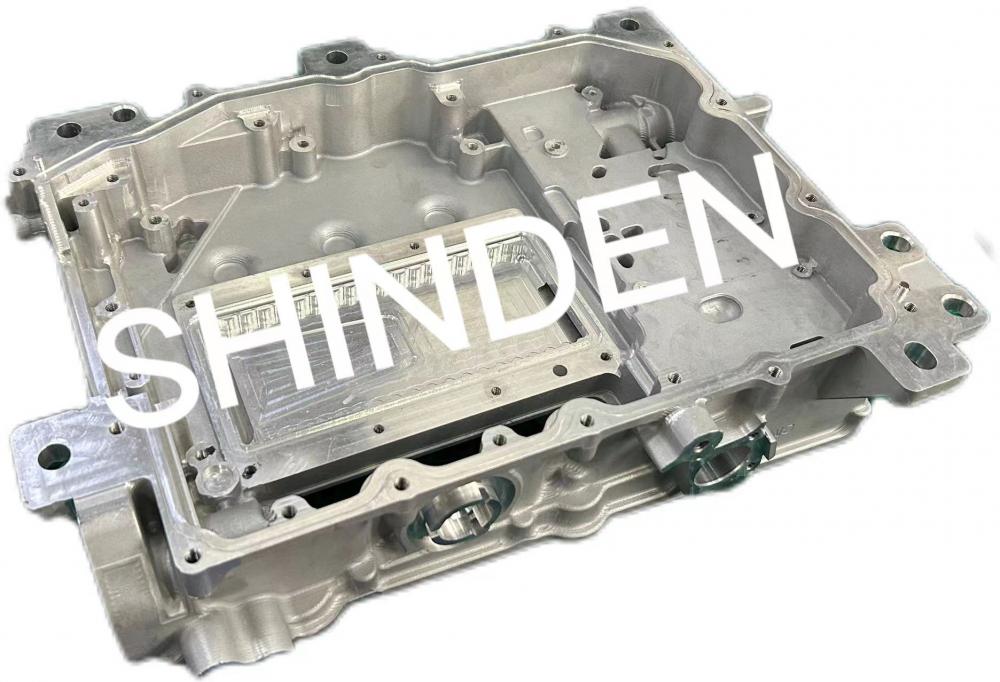

Model Number : 5 Axis CNC Turning Milling Machining Electric Cabinet

Place of Origin : China

Payment Terms : L/C, D/A, D/P, T/T

Delivery Time : 7-45 work days

Price : Provide according to demand

Casting Method : Low-Pressure Die Casting

Tolerance : ±0.1mm

Production Capacity : 1000-5000 pieces per month

Mold Material : Steel

Quality Control : ISO 9001:2015

Application : Automotive, Aerospace, Machinery, etc.

Heat Treatment : T6

Advantages : High precision, smooth surface, cost-effective

Material : Aluminum Alloy

Surface Treatment : Sand Blasting

Mold Life : 50,000-100,000 shots

Weight Range : 0.05kg-50kg

Dimension Range : Up to 1000mm

The manufacture of electric control box shell usually requires cutting, bending, welding, drilling, spraying and other processes. In the manufacturing process, it is necessary to ensure the accuracy, strength and durability of the housing to meet the requirements of the use of electrical equipment.

Established in 2010, Wuxi SHINDEN Modern Intelligent Technology Co.Ltd aims to become a first-class rapid manufacturing enterprise in China.

We are committed to helping companies' R&D and innovation by providing product display solutions and test prototype solutions.

Product display package solutions include delicate process display machine solutions, cutaway display machine solutions and transparent appearance display machine solutions, from processing, assembly to simulation of dynamic operation. The design and manufacture of the display stand is easy to assemble and disassemble, convenient for packaging and transportation, multiple solutions to choose from and professional customization to meet the multi-functional needs of different customers.

Small batch prototype solutions-engraving, short-cycle rapid prototype, suitable for new product development A sample, B sample stage. Small and medium batch prototype solutions - Casting, close to the characteristics of mass production die casting, suitable for new product development B and C stage and mass production up to 20,000 units/year. Test prototype solutions also include lubrication test, divided into transparent and translucent solutions, we have many years of rich experience in design and production, and we can customize solutions according to customer needs. We promise to provide professional and refined services to make our customers' products presented in the best way and help our customers’ R&D in the shortest time.

In the automotive field, we mainly serve the whole vehicle enterprises and core parts companies, with the service coverage of whole vehicle enterprises exceeding 95% and total service projects exceeding 10,000. We are also providing prototype and rapid medium and small batch manufacturing services for construction machinery, medical equipment, aviation and other industries. While deeply cultivating the domestic market, we are also carefully exploring foreign markets, mainly serving customers such as BorgWarner, Volvo, Bunch, Atlas, etc., mainly in Europe, North America, Oceania and other places.

|

|

5 Axis Precision CNC Machining Electric Vehicles Motor Case Aluminum Alloy Images |